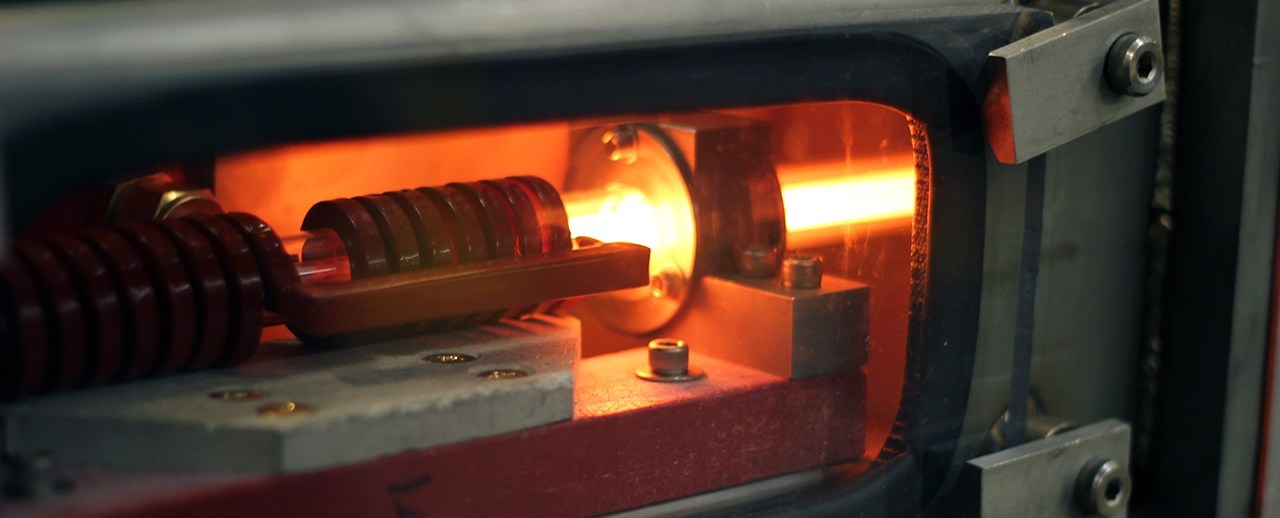

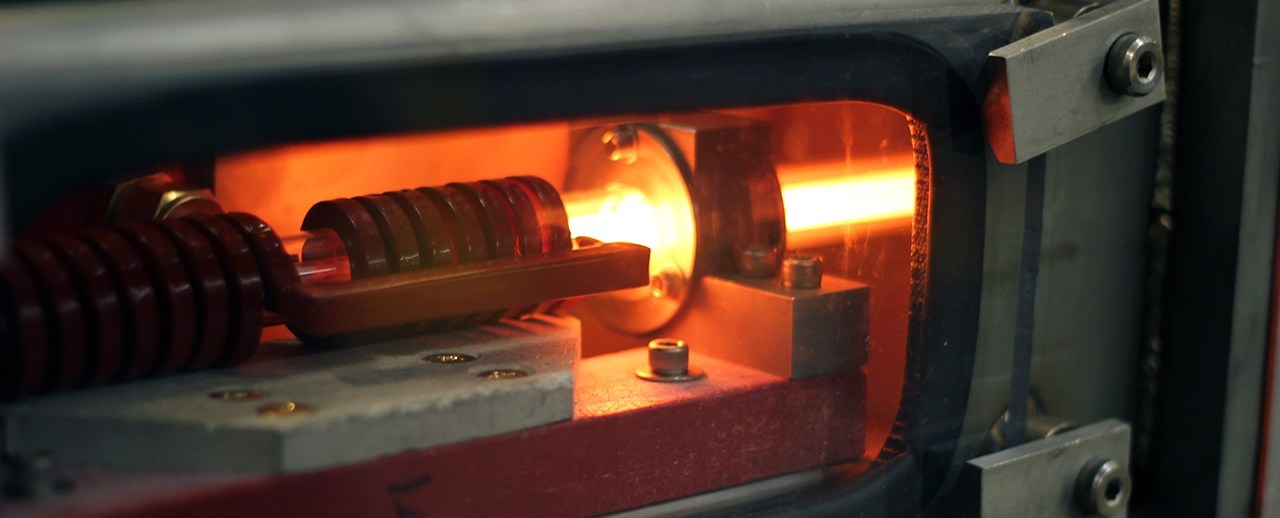

Bright Annealing

The bright annealing (BA) process for stainless steel pipes involves heating the pipes to high temperatures in a controlled atmosphere furnace to prevent oxidation. They are then rapidly cooled to maintain a smooth, reflective surface and enhance corrosion resistance, making them ideal for high-quality applications in industries like food and pharmaceuticals.

Inside and Outside Bead Crushing

Bead crushing on stainless steel pipes flattens the weld bead using a tool that applies pressure, creating a smoother surface. This improves fluid flow and reduces corrosion, making the pipes suitable for industries needing smooth internal surfaces, like food processing and pharmaceuticals.

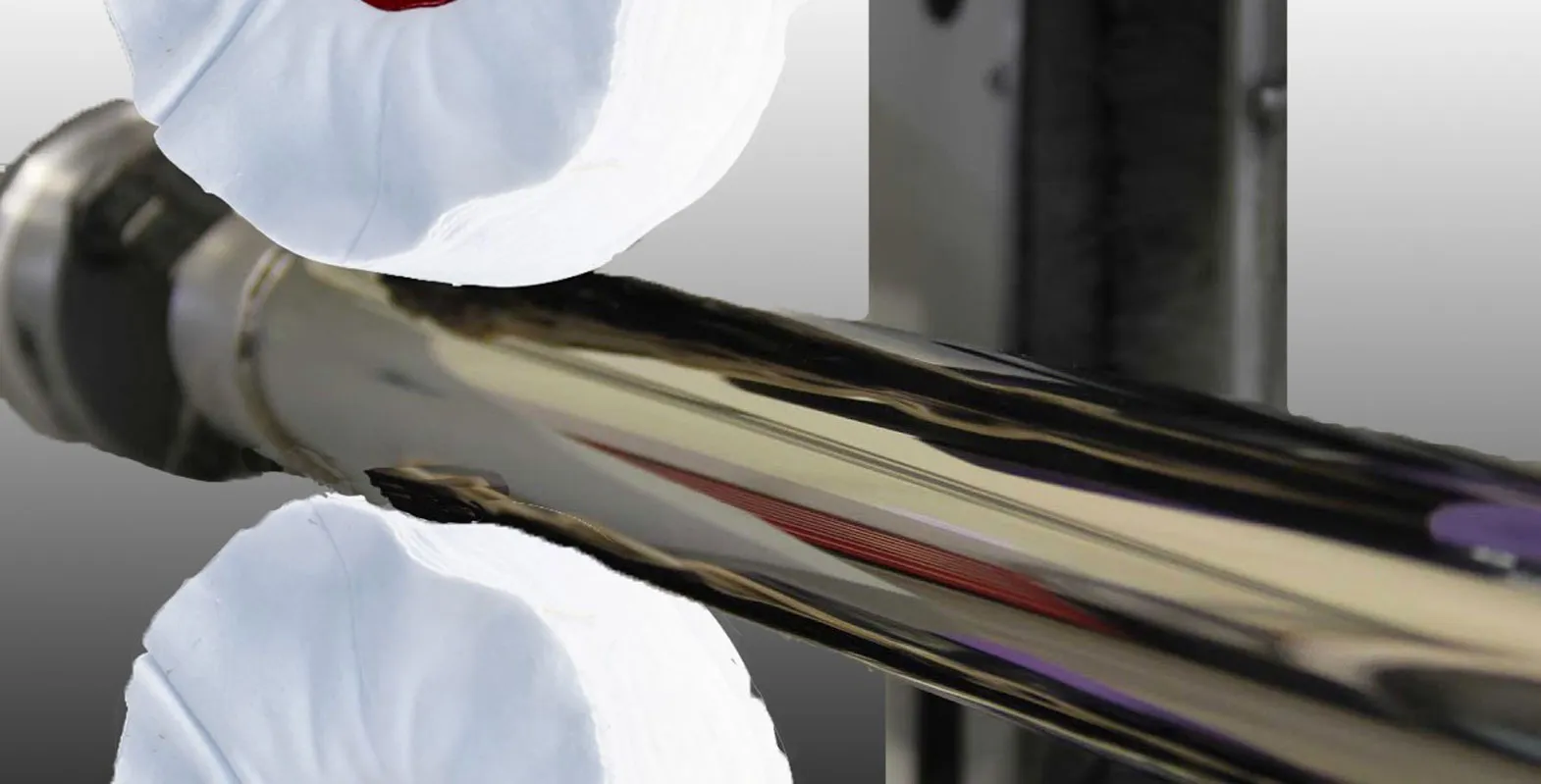

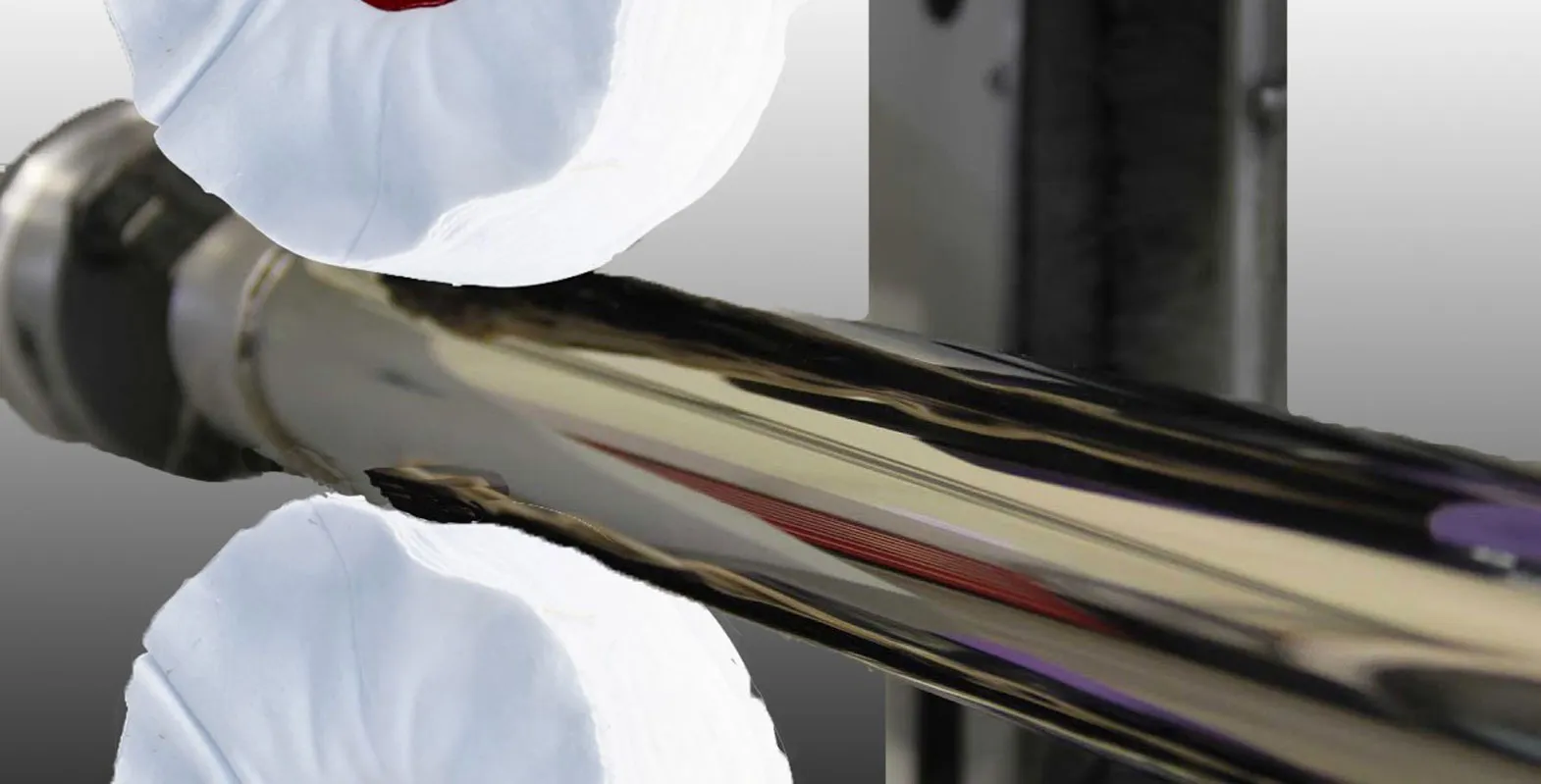

Mechanical Polishing

Mechanical polishing of stainless steel pipes uses abrasive materials in progressive grits to smooth the surface, resulting in a clean, shiny finish suitable for high-quality applications like food and pharmaceuticals.

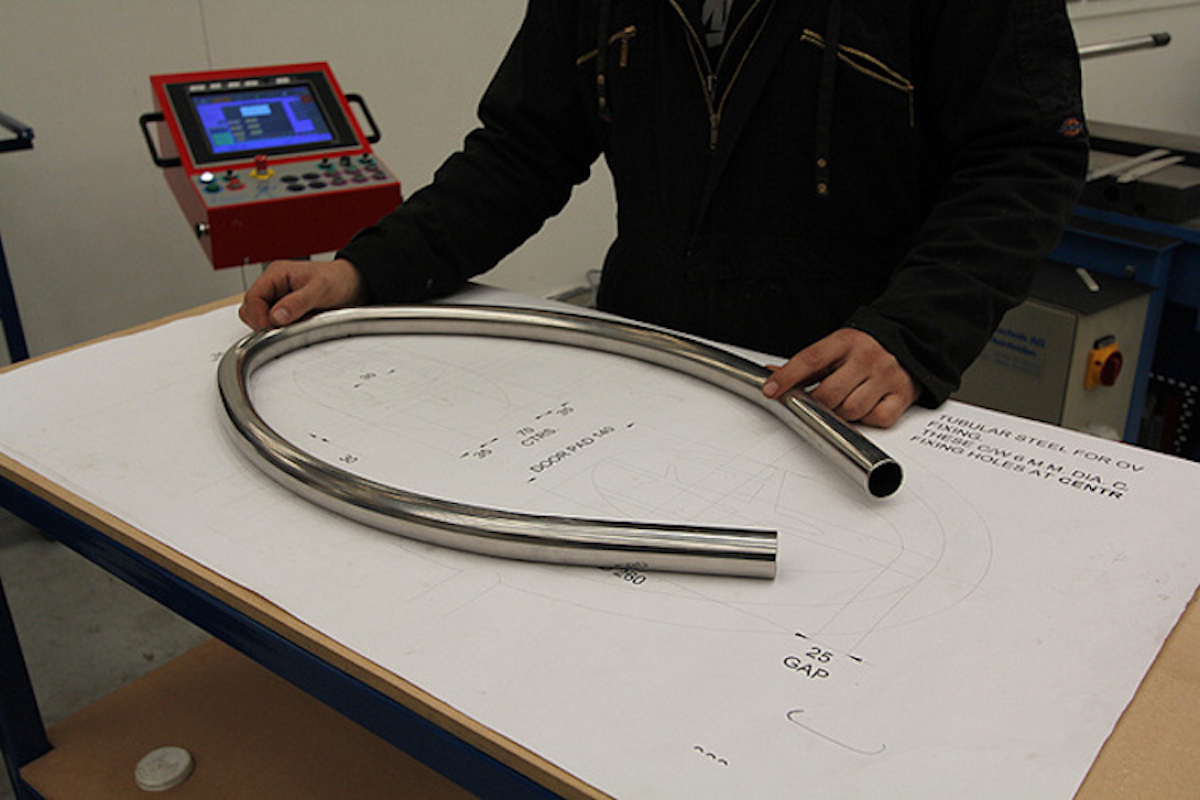

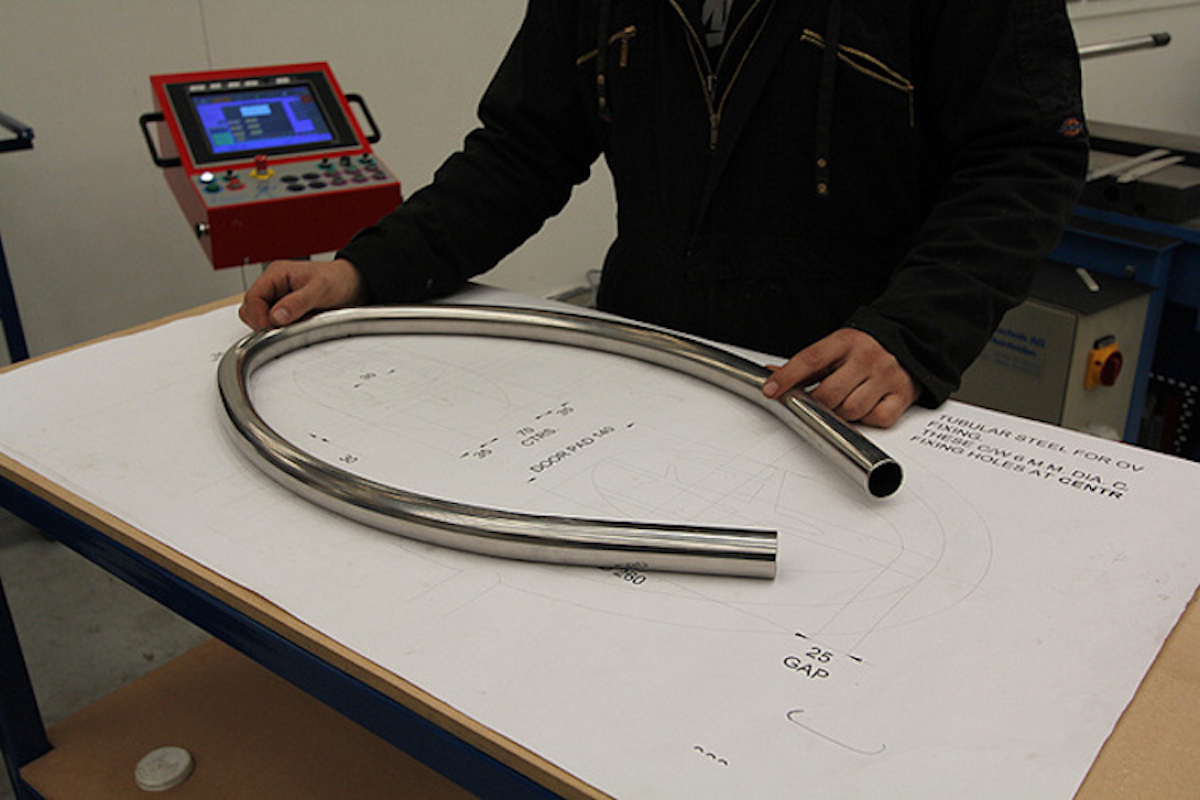

Forming and Bending

Forming and bending of stainless steel pipes involve reshaping them using dies, molds, and benders to achieve specific shapes and angles. This process ensures the pipes maintain their structural integrity while meeting the precise requirements of different applications, such as in construction and automotive industries.

Multiple Surface finishes

Matte finish is dull and non-reflective, ideal for hiding imperfections. Mirror finish is highly shiny and reflective, used for decorative purposes. Brushed finish features a satin texture with fine lines, giving a contemporary look. PVD finish offers a durable, reflective, or colored coating, enhancing both appearance and resistance.

The bright annealing (BA) process for stainless steel pipes involves heating the pipes to high temperatures in a controlled atmosphere furnace to prevent oxidation. They are then rapidly cooled to maintain a smooth, reflective surface and enhance corrosion resistance, making them ideal for high-quality applications in industries like food and pharmaceuticals.

Inside and Outside Bead Crushing

Bead crushing on stainless steel pipes flattens the weld bead using a tool that applies pressure, creating a smoother surface. This improves fluid flow and reduces corrosion, making the pipes suitable for industries needing smooth internal surfaces, like food processing and pharmaceuticals.

Mechanical Polishing

Mechanical polishing of stainless steel pipes uses abrasive materials in progressive grits to smooth the surface, resulting in a clean, shiny finish suitable for high-quality applications like food and pharmaceuticals.

Forming and Bending

Forming and bending of stainless steel pipes involve reshaping them using dies, molds, and benders to achieve specific shapes and angles. This process ensures the pipes maintain their structural integrity while meeting the precise requirements of different applications, such as in construction and automotive industries.

Multiple Surface finishes

Matte finish is dull and non-reflective, ideal for hiding imperfections. Mirror finish is highly shiny and reflective, used for decorative purposes. Brushed finish features a satin texture with fine lines, giving a contemporary look. PVD finish offers a durable, reflective, or colored coating, enhancing both appearance and resistance.

Send Inquiry

Send Inquiry Send SMS

Send SMS